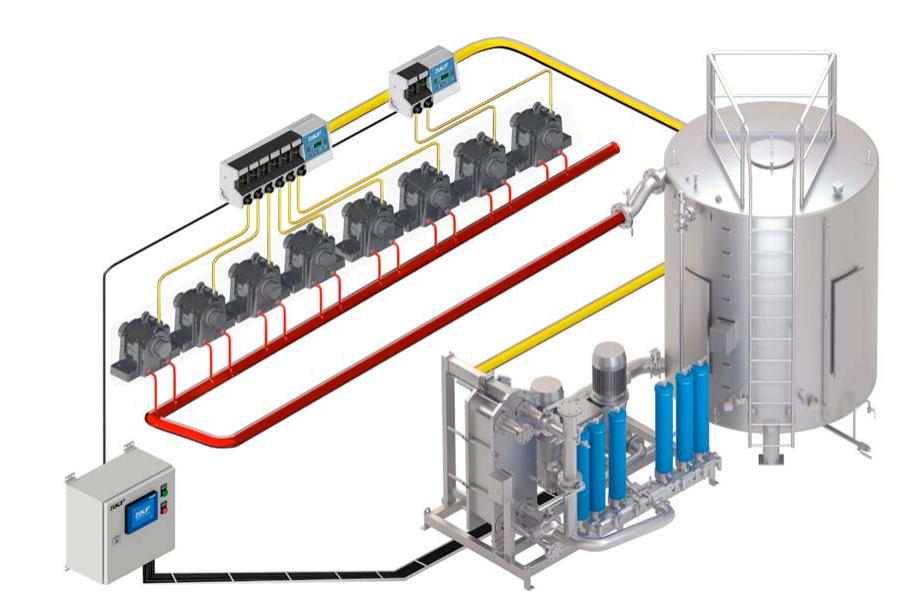

Oil circulation lubrication systems

Designed primarily to cool and lubricate highly stressed bearings in nearly every size of machine.

In addition to cooling, the oil flushes bearings and gearboxes, removing contaminants from friction points. Helping to assure accurate and reliable oil flow to each lubrication point, SKF CircOil systems include a wide range of customized and turnkey solutions for flow rates from 0,1–3.000 l/min. They are simple to service and feature a modular design that can be expanded easily.

Our patented tank design with the SKF plate separator technology increases operating efficiency to up to 90%. It efficiently removes air and water from the oil to prevent corrosion damage and premature oil deterioration. Adjustment valves with individual settings supply the oil to the lubrication points. They can be visually or electronically monitored and offer features for full digitalization and integration into data control systems supporting a more predictive maintenance approach.

Benefits

- Cooling of stressed bearings and gearboxes.

- Removal of particles from bearings and gearboxes.

- Oil reservoir sizes from 3 to 40 000 liters (0.79 to 10567 gal).

- High operating efficiency.

- Easy expansion of the lubrication system.

Applications

- Pulp and paper

- Metals

- Mining

- Automobile presses

- Automation

- Printing

- Food and beverage

- Explosive environments (ATEX / EEX) (upon request)

- API (upon request)