In today’s high-stakes industrial environments, durability, accuracy, and efficiency aren’t optional—they’re essential. Whether it’s for asset labels, compliance markers, or machine IDs, industrial tags must survive extreme conditions and remain readable over time. That’s where laser engraving excels. But what exactly is it, and how does it compare to other marking methods?

What Is Laser Engraving?

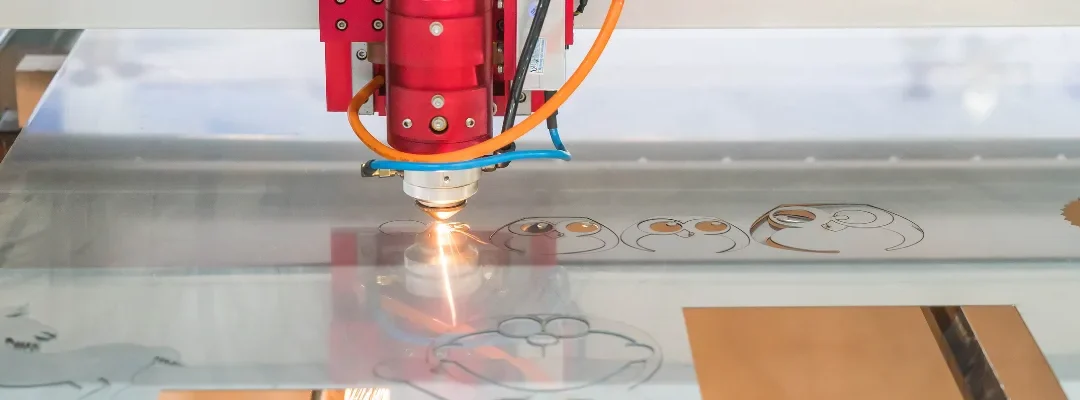

Laser engraving is a precision process where a focused beam of light permanently marks a material by etching or vaporizing its surface. Unlike mechanical or ink-based methods, laser engraving is non-contact and non-abrasive, enabling high-accuracy marking on materials like metals, plastics, ceramics, and composites.

Key Benefits of Laser Engraving

- Exceptional precision and resolution

- Contact-free operation—ideal for delicate surfaces

- Compatible with high-speed, high-volume production

- Resistant to heat, chemicals, and abrasion

Comparison Note:

Compared to dot peen marking (which can deform surfaces) or inkjet (which fades over time), laser engraving offers superior permanence and cleaner aesthetics, especially for compliance or safety-critical applications.

How Laser Engraving Works

Step-by-Step Process

- Laser Source Activation: A powerful laser generates a coherent light beam.

- Beam Delivery & Focusing: Mirrors and lenses guide and concentrate the beam onto the surface.

- Material Interaction: The focused energy alters or vaporizes material, forming a crisp, permanent mark.

- Software Control: CAD or vector software dictates speed, pattern, and depth with micrometer-level accuracy.

Types of Laser Technologies

- Fiber Lasers: Best for metals, with high-speed, high-contrast marks.

- CO₂ Lasers: Effective on organic materials like wood, leather, and plastic.

- UV Lasers: Designed for heat-sensitive surfaces, offering ultra-fine marking with minimal distortion.

Why Laser Engraving Is Essential for Industrial Tags

1. Extreme Durability

Laser-engraved tags withstand:

- Harsh chemicals

- Intense heat or cold

- UV radiation and abrasives

They maintain readability in sectors like oil & gas, automotive, and aerospace, where traditional inks or stickers fail.

2. Traceability & Compliance

Essential for:

- Regulatory standards (OSHA, ISO, FDA)

- Real-time tracking with barcodes, QR codes, and serial numbers

- Asset lifecycle documentation

3. Scalability with Customization

Whether producing 10 tags or 10,000:

- Syncs with ERP or inventory systems

- Enables automated, variable-data engraving (e.g., sequential IDs)

- Fast turnaround with minimal setup

4. Lower Total Cost of Ownership

While equipment costs may be higher initially, laser engraving pays off long-term through:

- No ink or tool wear

- Minimal maintenance

- Faster throughput vs. manual methods

Industry Applications

- Automotive: VIN plates, engine ID tags

- Aerospace: Compliance tracking for mission-critical components

- Oil & Gas: Rugged tags that survive corrosive or high-pressure settings

- Medical Devices: UDI markings that are biocompatible and permanent